|

BPI Fab’s XJ winch bumper |

Article by Brian Lindeman.

Editor’s note: BPI Fab is no longer making Jeep bumpers. Poison Spyder Customs is now producing this design.

When my wife made mince meat of a Ford Escort, the damage to the front of our Jeep ended up being minimal. (Bumper, Grille and Tranny Cooler needed replaced) While I waited for the insurance check to come I researched around for the bumper I wanted. I was torn between the Hanson Enterprise and Custom 4×4 bumpers when Jason referred me to BPI Fab bumpers. My mind was made up when I saw their price for the Trail Tuff winch bumper, $308 and they were located here in Denver. I contacted Tim at BPI Fab and he said they had just completed a bumper and that I could pick it up any time.

The next day I went across town and picked it up. For an extra charge they would have had it powder coated black but I opted for a bare metal bumper so I could have it powder coated green to match my Jeep. On my way home I dropped it off at Mile Hi Powder coating and picked the final color.

|

|

While I waited for the powder coating I could get to work on removing the factory bumper and prep for the new bumper. The factory bumper and bumper corners came off pretty easy with 6 torx bolts and 4-10mm bolts. Remove the 6 15 mm bolts that secure the factory bumper brackets to the frame. Keep 2 bolts for use in mounting the Trail Tuff bumper. 2-10mm screws held the vacuum canister to the factory bumper and are used to relocate it to the fender support. Mounting is easy, on the passengers side fender support drill a ¼ hole 6 ¾” from the existing hole, centered in the web of the support. Both horns had to be relocated as well, with a little pounding on the horn bracket, they could be reversed so they become invisible behind the bumper. (On models up ’96, front fender trimming is required) All was prepped waiting the freshly powder coated Trail Tuff bumper.

|

|

When I got the call my bumper was done I couldn’t wait any longer and rushed down the street to pick it up. The finish was beautiful and they even wrapped it up to protect it for the ride home.

|

|

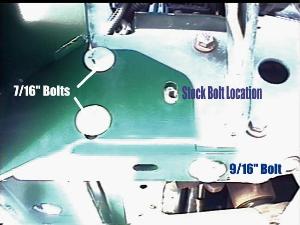

All the hardware included was straightforward and easy to comprehend. 2 nut plates were inserted through the frame rail holes on the front cross member before being lifted into place. For lifting the 70lb. bumper I enlisted the help of my next-door neighbor (Walter the ”Limo Man”). With the bumper in place and aligned to the stock holes we placed the 2-7/16” bolts and nuts in the front holes while the stock bolt was used in the 3rd mounting hole. 2-9/16” went through the bottom of the bracket into the nut plate that was inserted in the frame rails, and all bolts were torqued to 80lbs/ft. IT’S THAT SIMPLE.

|

|

I am extremely impressed with the final outcome of the BPI Fab Trail Tuff Bumper and have had many thumbs up and compliments on its looks. The approach angle has dramatically increased over the stock bumper and the D-ring tabs should make pulling simple. Tim at BPI Fab said it will accommodate most all winches and assures me that it is proven to be “TRAIL TUFF”.

Comments are off for this post